In 2020, Dannice chillers were fortunate enough to enter Guangxi liquor production enterprise as specialized refrigeration equipment, demonstrating excellent refrigeration performance during the brewing process. Below, Dannice chiller will take industry friends to learn about temperature control in wine brewing.

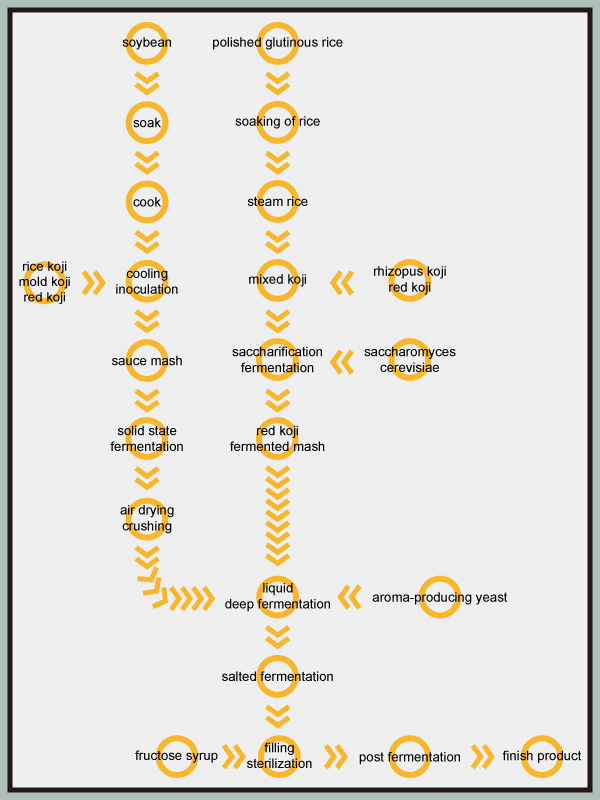

Alcohol fermentation is a complex biochemical process. Some fermentation processes involve a large variety and density of microorganisms, which can easily lead to low fermentation temperature and difficult process control. Excessive or low fermentation temperature can have adverse effects on production. High temperature can lead to rapid aging of microorganisms, while low temperature can hinder fermentation and affect the brewing cycle. Therefore, for temperature control, excellent and professional temperature control equipment is needed to provide temperature control, stabilize production, and improve product quality. Among them, brewing refrigeration equipment is an indispensable low-temperature control equipment.

The customer needs to invest in new refrigeration equipment to meet the production needs of the brewing workshop due to their investment in new projects. After searching for Dannice personnel through industry websites, and through later communication and comparison with other refrigeration equipment solutions, Dannice chillers were ultimately chosen.

In the refrigeration scheme, Dannice has provided customers with a set of 510KW dual compressor water-cooled screw refrigeration unit, equipped with a 6-ton stainless steel water tank for storing the produced chilled water. In the fermentation and cooling process of the brewing workshop, it also includes a -5 degree ethylene glycol refrigeration unit.

The Dannice water-cooled screw chiller adopts advanced design technology, manufacturing process, and efficient components. The compressor adopts leading industry brands such as Bizer/Hanzhong, comprehensively improving the unit's energy efficiency. At the same time, it can achieve stepless regulation of output according to load, making operation more economical; The unit adopts low noise components and is equipped with multiple high-quality components to achieve low vibration and high safety operating conditions.

Adopting advanced PLC/PC technology to achieve microcomputer control, with multiple safety protection functions such as phase, overload, high and low voltage; Equipped with real-time display functions such as exhaust temperature, ambient temperature, outlet and return water temperature, water pump operating time, high and low pressure values, and current values.

It is understood that the temperature of alcohol is generally controlled at 20 to 25 degrees Celsius, especially in summer, which is extremely difficult to control. Because of the fermentation process, in order to improve the brewing quality, most enterprises use constant temperature chamber technology for fermentation, so as to achieve the Dynamic equilibrium of the required time and fermentation output, which is in a small change range, and will not affect the fermentation due to temperature changes. As long as the optimal temperature range for fermentation is maintained and variable factors are well controlled, the best wine yield and taste can be achieved.

Later, after a follow-up visit by Dannice staff, it was found that the actual cooling effect was stable and reliable, ensuring stable production. Bringing considerable benefits to the enterprise.

ADD: Cofco Yunjing Plaza, Heshuikou Community, Matan Street, Guangming District, Shenzhen

wechat: Amy chen: +86 13650315101

+86 755 29941577

+86 755 29947530

Email: dnc@dannicechiller.com.