In the injection molding industry, extruders and injection molding machine equipment are important production equipment in industrial manufacturing. PE pipes, hoses, shaped plastics, rubber products, etc. are all produced through equipment such as extruders, and high production temperatures will also cause difficulty in demolding, slow molding, and do not meet the requirements of rapid manufacturing.

An enterprise mainly engaged in leather, textiles, luggage, and building decoration materials. Due to the expansion of the workshop, the extruder needs a dedicated chiller for cooling. Through industry channels, Shenzhen Dannice was found to select the chiller equipment for it.

Let's first take a look at several selection factors for the extruder,

1. Is there an open sink. In the case of an open water tank, when selecting a chiller, shell and tube or plate exchange evaporators should be used instead of coil evaporators; If there is no water tank or sink, a water tank coil evaporator can be used as a heat exchanger.

2. Reasonably calculate the cooling capacity of the chiller. The water temperature in the water tank of the extruder, the amount of water used per hour, and the return water temperature are important parameters for calculating and selecting a chiller. When selecting, it is important to consider the cooling margin of the extruder, which means that the selection should be slightly larger than the calculation in order to achieve the target cooling effect.

3. Choose the type of heat dissipation based on environmental conditions. Many manufacturing factories have cold water towers that can be fully utilized. Choosing water-cooled cold water is more economical and practical. Water cooled chillers are suitable for users with higher cooling stability and higher cooling power (such as 40hp50hp chillers) who use a water tower to dissipate heat. Therefore, it is advisable to choose a water cooled chiller with a cooling water tower for cooling; For situations where there is no cooling tower or it is not convenient to use a cooling tower, an air-cooled chiller can be chosen, as its flexibility is very good.

Based on the condition of the extruder equipment on site, working environment, temperature and humidity, and other parameters, Dannice technicians have selected the KC series air-cooled chiller as the dedicated chiller for the extruder. Dannice chillers have the following characteristics.

High quality compressor

Adopting imported compressors from Europe, America, and Japan, with built-in safety protection, low noise, power saving, and durability. Temperature control range 5 ℃ -30 ℃, error ± 0.5 ℃

Water tank evaporator

The stainless steel thick water tank evaporator is equipped with an automatic water replenishment device, which eliminates the need for expansion water tanks in engineering such as large temperature differences and small flow rates.

Water-cooled condenser

Made with new externally threaded copper pipes, it has a large heat dissipation capacity, compact size, compact structure, high reliability, beautiful appearance, and energy saving.

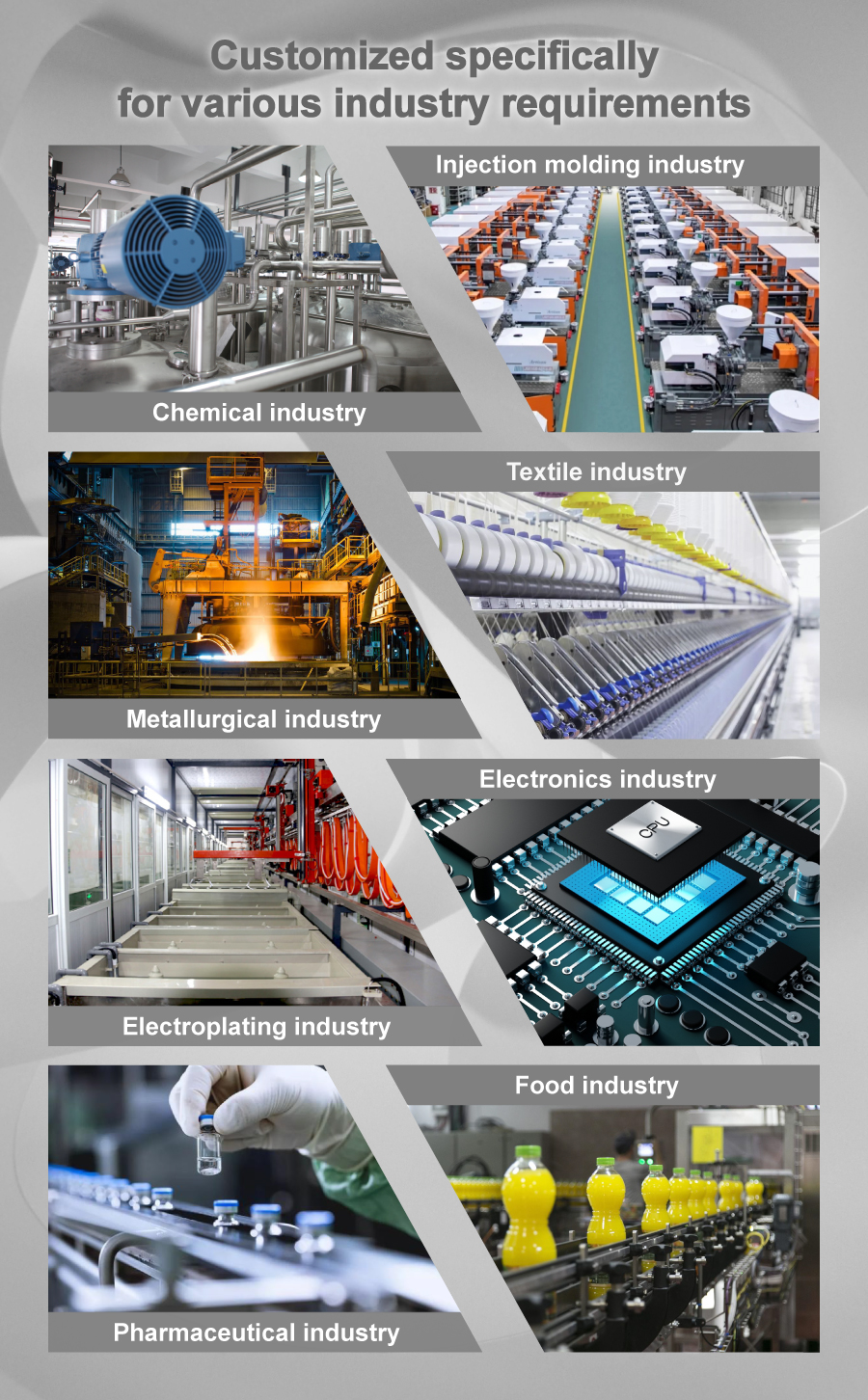

After actual debugging, the Dannice air-cooled chiller operates normally and perfectly matches the operating requirements of the chiller. The chiller is not only used in extruder equipment, but also in cooling or material temperature control of equipment such as reaction kettle, fermentation tank, calender, coating machine, coating machine, vacuum pump, etc.